Water vapor permeability is one of the main performance indexes of package materials. As people are attaching more importance to the damp proofing and waterproofing of products, package materials with smaller water vapor permeability becomes the f.3us of package material development and application and is receiving more and more concentrations in recent years. Package manufacturers, material suppliers, product manufacturers and inspection centers are introducing water vapor permeability instruments one after another to intensify their efforts on material water vapor permeability testing. Most of the water vapor permeability instruments on sale are either of the Cup Method kind or of the sensor kind.

ASTME 96 is one of the standards for cup method, in which not only the common Desiccant Method commonly seen in other standards is elaborated, the water method that is of equal significance with Desiccant Method in water vapor permeability testing is also introduced.

1. Summary of Cup Method

Cup method is the method used to test water vapor permeability independently based on a simple and perspicuous principle. In cup method, there is certain pressure difference maintained on two sides of the specimen. Parameters relating water vapor permeability is calculated after testing the water vapor transmission rate of the specimen under specified temperature and relative humidity. Cup method can be operated into two ways based on the same testing principle: Desiccant Method in which water vapor transmits into the test dish, and water method in which water vapor transmits out of the test dish.

The purpose of these tests is to obtain, by means of simple apparatus, reliable values of water vapor transfer through permeable and semi permeable materials, expressed in suitable units. These values are for use in design, manufacture, and marketing.

2. Testing Principle of Desiccant Method and Water Method

Both Desiccant Method and water method are considered as basic testing methods in ASTM E 96. The test methods are limited to specimens not over 1 and 1/4in. (32mm) in thickness…Two basic methods, the Desiccant Method and the Water Method, are provided for the measurement of permeance.

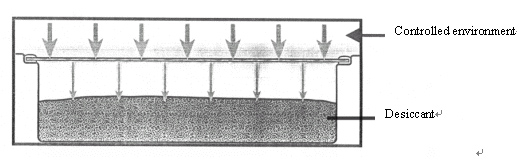

In the Desiccant Method the test specimen is sealed to the open mouth of a test dish containing a desiccant, and the assembly placed in a controlled atmosphere. Periodic weighings determine the rate of water vapor movement through the specimen into the desiccant. Fig.1 is the testing principle of desiccant method.

Fig.1 testing principle of desiccant method

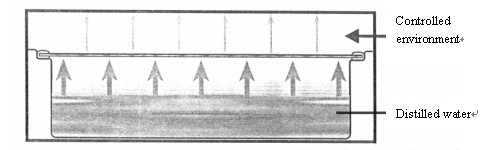

In the Water Method, the dish contains distilled water, and the weighings determine the rate of vapor movement through the specimen from the water to the controlled atmosphere. Fig.2 is the testing principle of water method.

Fig.2 testing principle of water method

The vapor pressure difference is nominally the same in both methods except in the variation, with extremes of humidity on opposite sides.

Application field of cup method should be illustrated here: ASTM E 96 is not only suitable for water vapor permeability testing of package material such as plastic film, paper, and fiberboard, it is also applicable in the testing of gypsum, plaster products and wood products. Therefore, the standard has a lower requirement for thickness of specimen. For specimen with bigger thickness, to avoid edge leaking is of great significance. However, in package testing industry, specimen of great thickness is rather rare. That is why the following part will not deal with such kind of specimen, though it is part of the ASTME 96.

3. Testing

In the cup method, at least three assemblies are needed: test dish, testing environment and weighing appliance.

3.1 test dish

The test dish shall be of any noncorroding material, impermeable to water or water vapor. It may be of any shape. Lightweight is desirable. A large, shallow dish is preferred, but its size and weight are limited when an analytical balance is chosen to detect small weight changes. Different depths may be used for the Desiccant Method and Water Method, but a 3/4 in. (19mm) depth (below the mouth) is satisfactory for either method.

The easily folding or distorting specimen will need an external edge or frame at the open mouth of test dish for supporting. Normally, extreme thin specimen needs such assistance.

3.2 testing environment

The test environment is realized in testing chamber. Its temperature should remain within + 1 °C and humidity within + 2 % . Air shall be continuously circulated throughout the chamber, with a velocity sufficient to maintain uniform conditions at all test locations. Generally speaking, temperature is often controlled by single-heat because the testing temperature is always higher than lab temperature.

3.3 weighing appliance

In ASTM E 96, the teat dish is weighed by analytical balance. However, it can also be weighed in other ways. The standard has some requirements for balance sensitivity. The balance shall be sensitive to a change smaller than 1% of the weight change during the period when a steady state is considered to exist. Therefore, balance of higher sensitivity will shorten the weighing interval and balance of lower sensitivity will consequently prolong the interval. The high precision analytical balance or other higher precision weighing appliance is desired in enhancing the testing accuracy and shortening the testing period.

4. Specimen Preparation

The material shall be sampled in accordance with standard methods of sampling applicable to the material under test. The sample shall be of uniform thickness. If the material is of nonsymmetrical construction, the two faces shall be designated by distinguishing marks. ASTME 96 has a detailed specification of specimen number and sampling manner under different conditions.

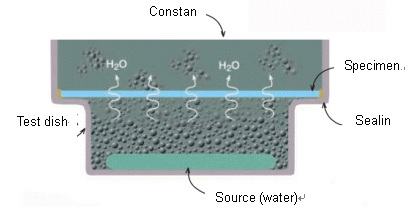

Attach the specimen to the dish by sealing (and clamping if desired) in such a manner that the dish mouth defines the area of the specimen exposed to the vapor pressure in the dish. Thoroughly seal the edges of the specimen to prevent the passage of vapor into, or out of, or around the specimen edges or any portion thereof.

The effectiveness of specimen attachment has a direct influence on test accuracy. Specimen edge sealing is the most important procedure and it is commonly completed in ways of wax seals or gasketed seals.

The process of wax sealing is rather complex. Prepare sealing wax according to certain proportion and then heat it to melting state. Pour the wax to the edge of test dish and clean the pouring place after the wax has cooled and shaped.

Gasketed seals have a better adaptability and operability than wax seals. Gasketed types of seals are also in use on appropriately designed dishes. These simplify the mounting of the specimen, but must be used with caution, since the possibility of edge leakage is greater with gasketed seals than with wax seals.

The completed specimen attachment is as follows:

5. Test Process

The whole testing process includes specimen balancing, periodic weighing and transmission equilibrium judgment. Test can be finished when the specimen has achieved transmission equilibrium.

5.1 test process of Desiccant Method

Fill the test dish with desiccant……Leave enough space so that shaking of the dish, which must be done at each weighing, will mix the desiccant. Attach the specimen to the dish and place it in the controlled chamber……Weigh the dish assembly periodically, often enough to provide eight or ten data points during the test. At first the weight may change rapidly; later a steady state will be reached where the rate of change is substantially constant.

5.2 test process of water method

Fill the test dish with distilled water……The air space thus allowed has a small vapor resistance, but it is necessary in order to reduce the risk of water touching the specimen when the dish is handled. Such contact invalidates a test on some materials such as paper, wood, or other hygroscopic materials. Attach the specimen to the dish. Weigh the dish assembly and place it in the controlled chamber on a true horizontal surface. The rest process is the same with that of the Desiccant Method, i.e. weigh the test dish periodically until the rate of change is substantially constant.

5.3 calculate results

Desiccant Method and water method is introduced in two parts in ASTM E 96, but the data processing method is consistent.

Calculate the water vapor transmission, and permeance as follows.

WVT=G/tA=(G/t)A

- G = weight change (from the straight line), g

- t = time, h

- G/t = slope of the straight line, g/h

- A = test area (cup mouth area), m2

- WVT = rate of water vapor transmission, g/h·m2

-

-

- p = vapor pressure difference, mmHg

- S = saturation vapor pressure at test temperature, mmHg

- R 1 = relative humidity at the source expressed as a fraction (the test chamber for desiccant method; in the dish for water method)

- R 2 = relative humidity at the vapor sink expressed as a fraction

The two methods commonly used in data processing are graphic analyzing and digital analyzing. The combination of the most advanced computer digital analyzing at present time can reduce the gap of accurate weighing region point infinitively and can analyze the data more visually. Monitor software of Labthink TSY-T1 and TSY-T3 possess powerful functions of data collecting, graphic constructing and data analyzing as well.

fig.5. Labthink TSY-T3 monitor software

6. Precautions

6.1 the selection of testing environment

A permeance value obtained under one set of test conditions may not indicate the value under a different set of conditions. For this reason, the test conditions should be selected that most closely approach the conditions of use. The appendix of ASTME 96 has listed several groups of standard test conditions for selection.

6.2 error caused by specimen attachment

When the specimen area is larger than the mouth area, this overlay upon the ledge is a source of error, particularly for thick specimens. The overlay material results in a positive error, indicating excessive water vapor transmission. The magnitude of the error is a complex function of the thickness, ledge width, mouth area, and possibly the permeability.

6.3 test time

Analytical balance used in earlier cup method is usually of less high precision and manual operation may cause certain influence (less influenced if the water method is completed in test environment) on transmission equilibrium. This will result in a longer testing time of earlier water method. By modifying the testing process, full automatic tester of water method with high precision weighing assembly can complete the test both in controlled environment and full automatically. The testing time for specimen of medium permeability, which will always last several days in earlier water method, will only cost several hours now.

6.4 dummy specimen

When results of water vapor transmission are expected to be less than 0.05 perm, a dummy specimen is strongly recommended. Such a dummy specimen should be attached to an empty cup in the normal manner. The environmental effects of temperature variation and buoyancy variability due to barometric pressure fluctuation can be arithmetically tared out of the weighing values. This precaution permits earlier and more reliable achievement of equilibrium conditions. As a further precaution when gasketed seals are used instead of preferred sealants, a blank test run is suggested using glass or metal as a dummy specimen.

7. Summary

ASTME 96 is the most comprehensive standard on cup method being compiled up till now. In ASTME 96, cup method includes desiccant method and water method. The two methods are based on the same testing principle. Test dish, test environment and weighing appliance are the main assemblies in cup method and not a single one can be omitted. The process of specimen attachment is complicate but has a direct influence on test result. Test result of dummy specimen will influence the analyzing and calculating of test result greatly. The adoption of professional software will provide powerful function of data analyzing.